Generator alternator rewinding service is a vital part of the regular maintenance of your automobile. This process is crucial to extend the life of the alternator. In addition, alternator rewinding also helps prevent electrical problems in your vehicle. In this article, we’ll discuss the importance of rewinding and the process involved.

Regular Maintenance of Alternators

Regular maintenance of generator alternators is essential to ensure their proper working condition. It is important to ensure that all of their parts are in good condition, such as the air filter. To perform the maintenance, the generator should be disconnected from the power supply and cleaned. It is also important to remove all dust, dirt, and debris from the alternator’s interior and exterior. After cleaning the alternator, it should be thoroughly dried. It is also essential to regularly check for abnormal voltages and noises.

Another thing to check is the winding resistance. If the windings are dirty and not properly insulated, they will short to the ground or each other. To check the resistance of the windings, consult the manufacturer’s guidelines.

Importance of Alternator Rewinding

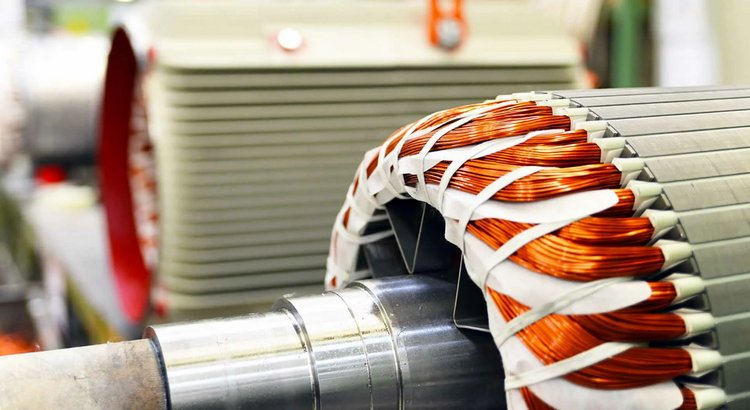

Rewinding your generator alternator is one way to improve its performance. The process involves stripping the old windings from the stator core and replacing them with new ones. It takes a lot of care to make sure that all the windings are properly connected and braced. Any mistake in this process can cause the windings to fail. The new windings are then varnished to prevent contaminants and provide electrical insulation.

Another way to recognize if your alternator needs to be rewound is to check its performance. Failing alternators are often accompanied by other symptoms, like dim or flickering headlights. Your windows may also roll up and down more slowly than usual. Also, your backup camera may not function properly. If you notice any of these signs, it is time to have the alternator checked.

Process

The alternator needs regular intervention to maintain mechanical integrity and optimal performance. It can be affected by moisture, airborne debris, and the failure of the engine’s main crank seal. These issues can result in a breakdown of insulation and inefficient voltage production. Oil absorbed into windings can also cause the voltage to become unstable. A faulty alternator could eventually fail completely.

The main purpose of generator alternator rewinding is to improve the efficiency of the generator. The stator has a core composed of thin sheets of magnetic steel. Steel is a strong electrical conductor, but it would short circuit if it were solid. To avoid this, thin sheets of steel are laminated, which breaks up the conducting path along the stator’s length. Lamination also helps keep the power losses in the stator steel at a minimum.

Source: ghaimagroup.com

Soccer lover, band member, front-end designer. Doing at the junction of art and mathematics to craft meaningful ideas that endure. I work with Fortune 500 companies and startups.